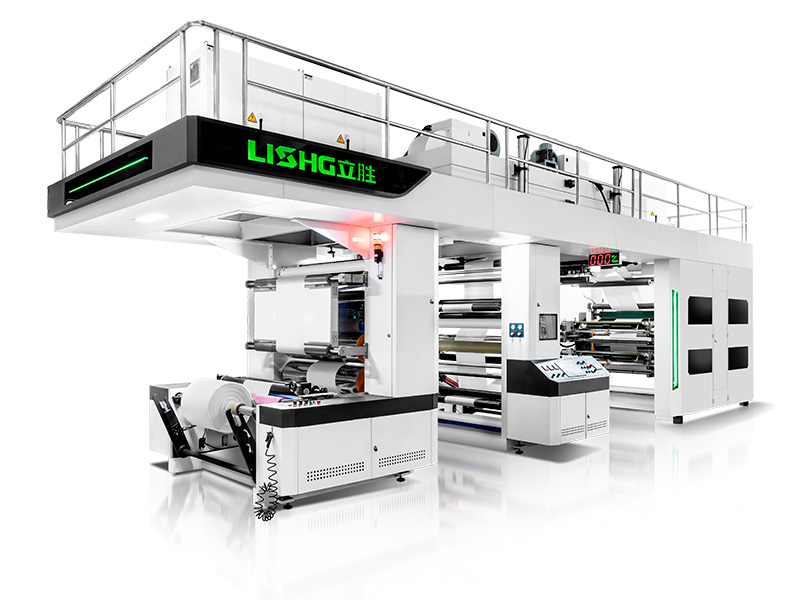

CI Flexo Printing Machine

CI flexo printing press, also known as central impression flexo printing press, is designed to provide high-quality printing for a variety of flexible packaging materials. The central cylinder design ensures excellent color registration and stability during the printing process, making it an ideal choice for printing complex and multi-color designs. This type of machine is widely used in industries such as food packaging, pharmaceuticals, and consumer goods, offering efficient and consistent printing performance

With 20 years of independent production and R&D experience, we strictly adhere to the ISO9001 quality management system. We have introduced Mazak and Gantry machining centers, offering extremely high precision and self-developed capabilities. Each machine undergoes comprehensive testing and inspection before delivery.

Our equipment is certified with CE, ISO9001, and other international certifications, ensuring compliance with global quality and safety standards.

Our company covers an area of 35,000 square meters, equipped with advanced production facilities and equipment.

Our factory currently employs over 100 people, including more than 20 professional sales personnel and over 10 after-sales engineers.

We are an integrated manufacturing and trading enterprise with 20 years of independent production facilities and research and development capabilities.

Our factory is located at 669 Nanbin Street, Ruian City, Wenzhou, Zhejiang Province, China. The location is convenient, and we welcome customers to visit and inspect at any time.

We actively participate in various domestic and international exhibitions, having attended over 100 exhibitions to showcase our latest products and technologies.

We primarily offer three types of printing machines: CI flexographic printing machines, stack flexographic printing machines, and fully servo sleeve flexographic printing machines. Our products are widely used in plastic films, paper, non-woven fabrics, and PP woven bags.

We offer customization services and can design and manufacture machines according to the specific needs of our customers.

We provide detailed operation manuals and training videos to help customers better understand and use our equipment.

The delivery time depends on the customer’s customization requirements, generally ranging from 30 to 120 days.

Our equipment production meets ISO9001, CE, and other international standards, ensuring high performance and safety levels.

The equipment will be packaged according to export standards and will be treated to prevent damage and rust before delivery

We provide comprehensive after-sales services, including equipment installation, debugging, training, and maintenance support. Our team of service engineers can provide on-site support globally to address any issues.

The warranty period for the delivered equipment is 12 months after the completion of installation, but no later than 12 months after shipment. If any part proves to be defective and the damage is confirmed by the seller’s technicians within this period, the seller will either send an engineer to repair it or supply a new replacement part free of charge

The warranty does not cover regular spare parts or parts damaged due to normal wear, abnormal operation, improper maintenance, and inadequate civil works. The seller is not liable for any production loss under any circumstances

If the equipment proves defective during the warranty period and the damage is confirmed by the seller’s technicians, the seller will either send an engineer to repair it or provide a new replacement part free of charge

The seller will send one engineer to the buyer’s factory to install and test the printing machine and train the buyer’s workers. The entire installation and training process is expected to take one week.

The buyer needs to cover the following costs: • Engineer’s salary: USD 220/day, depending on the engineer's performance satisfaction. The dates of arrival and departure are counted as paid days. • Visa costs • Round-trip air tickets • Accommodation, transportation, food, medical care, and safety costs in the buyer’s country • Any other related costs incurred in the buyer’s country Additionally, the buyer should prepare enough labor, electric wire outside the control panel, and tools for the installation

The engineer’s salary is USD 220/day, depending on the satisfaction with the engineer’s performance. The dates of arrival and departure are counted as paid days. The days spent waiting for spare parts, which are the seller’s responsibility, are not included in the salary payment

Lisheng Packaging Machinery

Internal Team

Phone | 0577-58189489

Mobile | +86-15888781903 (whatsapp)

Email | [email protected]

Address | No.669, East 2nd Road,Nanbin Street. Rui'an City, Wenzhou City, Zhejiang, China.