Flexo Printing vs Offset Printing: 8 Key Differences

Printing technology has evolved significantly, with various techniques available for different applications. Among them, flexo printing and offset printing are two widely used methods. But what exactly are they, and how do they compare? This article will explore flexo printing vs offset printing, their differences, and how to choose the right one for your needs.

What is Flexographic Printing?

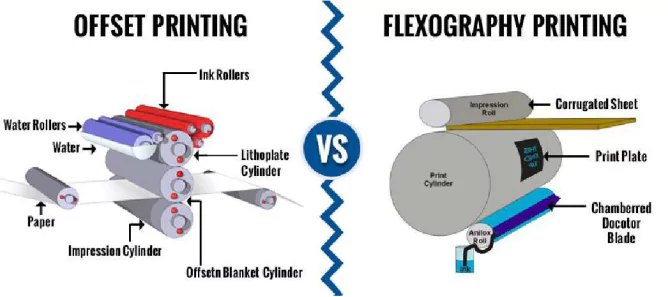

Flexographic printing (flexo printing) is a high-speed printing process that uses flexible relief plates to transfer ink onto various substrates. It is widely used for packaging materials, labels, newspapers, and flexible plastics.

What is Offset Printing?

Offset printing, also known as machine offset printing, is a traditional method that transfers ink from a plate to a rubber blanket and then onto the printing surface. It is commonly used for high-quality print jobs such as magazines, brochures, and business cards.

8 Difference Between Flexo and Offset Printing

| Aspect | Flexo Printing | Offset Printing |

| Ink Type | Fast-drying, water-based, solvent-based, or UV-curable | Oil-based or UV inks, requires more drying time |

| Plate Material | Flexible rubber or photopolymer plates, reusable | Rigid aluminum plates, require more maintenance |

| Cost | Higher initial cost but cost-effective for long runs | Lower plate costs but expensive for short runs |

| Run Length | Ideal for long-run jobs like packaging and labels | Best for medium to large high-quality print jobs |

| Print Quality | Good, but less detailed than offset printing | Sharp images and fine details for high resolution |

| Maintenance | Requires regular plate cleaning, durable for long use | Frequent plate changes, complex ink balancing |

| Materials & Substrates | Prints on plastic, metal, paper, and cardboard | Mainly for paper-based materials |

| Print Speed | High-speed printing, efficient for bulk production | Slower due to setup and ink drying |

1. Ink Type

Flexo printing uses flexo ink printing, which is fast-drying and can be water-based, solvent-based, or UV-curable.

Offset printing relies on oil-based or UV inks, which provide excellent color accuracy but require more drying time.

2. Plate Material

Flexo printing plates are flexible, made from rubber or photopolymer, and can be reused multiple times.

Offset printing plates are rigid and typically made of aluminum, requiring more maintenance and periodic replacement.

3. Cost

Flexo printing has a higher initial cost due to plate-making expenses but becomes cost-effective for long runs.

Offset printing has lower plate costs but is more expensive for short-run jobs due to setup time.

4. Run Length

Flexo printing is ideal for long-run printing jobs, such as packaging and continuous label production.

Offset printing is better suited for high-quality, medium to large print jobs, such as books and marketing materials.

5. Print Quality

Offset printing delivers sharper images and finer details, making it the preferred choice for high-resolution prints.

Flexo printing has improved over the years but may not match offset quality in fine detail reproduction.

6. Maintenance

Flexo printing requires regular plate cleaning and adjustments but is more durable for long-term use.

Offset printing requires frequent plate changes and a more complex ink balancing process.

7. Materials and Substrates

Flexo printing can print on various materials, including plastic, metal, paper, and corrugated cardboard.

Offset printing is mainly used for paper-based materials, limiting its flexibility.

8. Print Speed

Flexo printing operates at higher speeds, making it efficient for bulk production.

Offset printing takes longer due to setup time and ink drying requirements.

Choose the Flexographic Printing Machine at Lishg

If you decide that flexographic printing suits your needs, Lishg offers high-quality flexo printing machines that ensure efficiency, durability, and excellent print quality. Our machines provide superior performance for packaging, labeling, and industrial printing, making them a smart investment for your business.

Conclusion

Understanding the difference between flexo and offset printing is essential for selecting the right method for your project. Flexo printing is the go-to choice for high-speed, cost-effective packaging and label production, while offset printing remains the standard for high-quality, paper-based prints. Choose wisely based on your specific needs, and if flexo printing is the right fit, explore Lishg’s flexo printing machines for the best results.

References

1 Flexo vs. Offset Printing (The 3 Main Differences Explained)

2 Flexo vs. Offset Printing: The Differences Explained

3 Flexo Printing vs Offset Printing: Understanding the Differences