Main parameter:

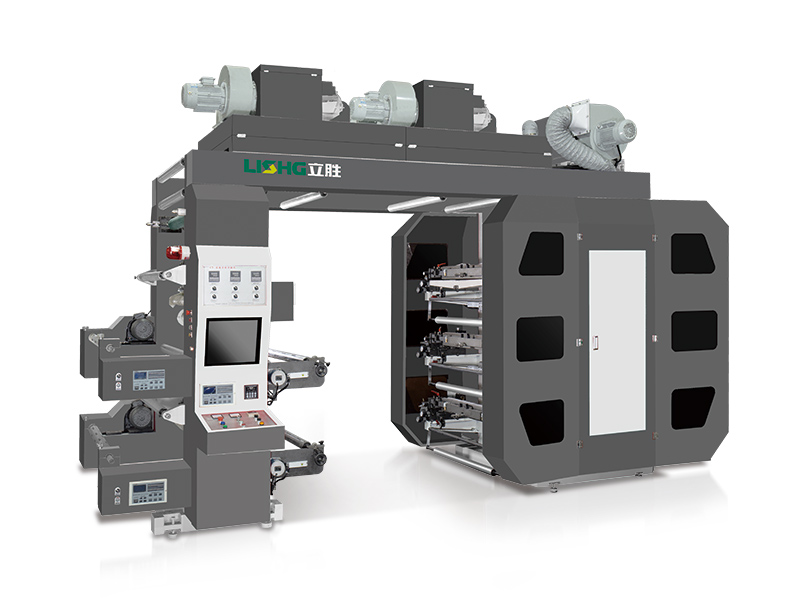

| Model |

YTB |

| Type |

Stack |

| Standard Machine width |

600mm 800mm 1000mm 1200mm |

| Material Feeding Width |

200-1600mm, also can customized for more width material |

| Printing Width |

160-1560mm, also can customized for more width material |

| Printing Length |

Standard is 400mm,can customized from 300-1000mm |

| Max Machine Speed |

100 m/min |

| Printing Speed |

10-80 m/min

Equip chamber doctor blade can reach 100m/min |

| Register precision |

≤0.3mm |

| Thickness of plate |

1.14mm 1.7mm 2.28mm 2.84mm 3.94mm can customized |

| Gear |

1.5mm |

| Transmission |

Synchronous Belt |

| Heating |

Electricity Heating |

| Double tape thickness for stick plate |

0.38mm 0.5mm can customized |

Printing sections:

1. plate roller circumference: 300-1000mm, standard less than 400mm

2. print material: resin plate or rubber plate

3. Transmission between printing roller and anilox roller: Helical gears

4. printing chromatography: 360-degree rotation

5. adjustment method: By Manual (Automatic printing after adjust by manual, when start machine, no need register color again, the printing pressure and register all keep the same.)

6. Printing roller lifting system: pneumatic

Print Sample:

Paper

Film

Our Service

|

|

Pre-Sales One-stop Service

* Inquiry and consulting support

* Latest industry trends

* More fit printing solution

* Sample testing support

* View our Factory

* Suggest layout support |

After-Sales Service

* One year warranty

* Machine test video before delivery

* English Manual, Electric Diagram

* Training how to install the machine,

* training how to use the machine

* Engineers available to service machinery overseas |

Our company pictures let you know about my company